The Group

Pantani Group is a unified and cohesive group of companies specialized in tube bending, finning, corrugation and custom cutting, used in oil & gas, chemical & petrochemical, geothermal, renewable energy plants, automotive, nuclear and many other sectors.

For over 30 years, we have been guided by the following values: specialization, punctuality, attentive listening and customer care, collaboration, reliability and flexibility.

U-bent tubes and square-shape bent tubes for shell-and-tube heat exchangers.

Bent Tubes

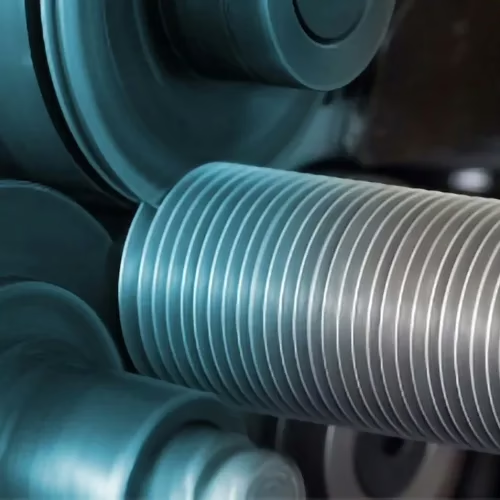

Low fin tubes or low fin tubes with internal ribs produced by cold rolling.

Low Fin Tubes

Significant improvements in heat transfer and energy efficiency.

Manufactured by tightly winding a metal strip under tension around the tube surface.

Applied-Fin Tubes

G-FIN tubes with embedded fins and thermal resistance up to 430°C.

G-FIN Tubes

L-FIN tubes for heat exchangers and air coolers, suitable for temperatures up to 130°C.

L-FIN Tubes

Overlapping L-shaped fins for enhanced corrosion protection and performance up to 180°C.

LL-FIN Tubes

KL-FIN tubes with knurled fin, ideal for heat exchangers and air coolers up to 260°C.

KL-FIN Tubes

Metal tubes with an inner base tube clad with an aluminum sleeve.

Extruded Tubes

Why

Pantani Group

Pantani Group presents itself to the market as an authoritative partner, offering a wide range of customized solutions through a single point of contact.

With over 30 years of professionalism, technical expertise and shared values across the Group, our customers continue to choose us, awarding us an average rating of 9.5/10.

Our Numbers

0 %

On-time deliveries / year

+ 0 k

Bent tubes / year

+2.5 mln

Finned meters/year

+ 0 mln

Custom cuts / year

+ 0

Years of experience

Our Strengths

Specialization

We put our long-standing, high-level technical expertise at your disposal to deliver high-quality tube processing solutions, consistently reliable over time.

On-time delivery

Meeting our commitments is one of the pillars on which our professional relationships are built.

Listening & customer focus

Active listening and empathy guide the way we work, both within the Group and with our customers. We are truly present in what we do, from the smallest details to the most complex solutions.

Collaboration

We stand alongside our people, customers and suppliers at all times. We believe in the value of every individual and in the power of teamwork.

Reliability

For over 30 years, we have been a leading Italian reference in tube bending, finning and corrugation. We take care of our customers’ needs and the results they aim to achieve.

Flexibility

We are both concave and convex: we listen to our customers’ ideas and perspectives and adapt to each situation according to their specific requirements.

Proactively by your side to:

Optimize production processes

Save time and costs

Ensure delivery times

3 February 2026

Production variables: how to reduce them and improve heat exchange efficiency

Process control, material quality, and technical expertise: this is the approach to eliminating waste and protecting results.

In every production process, unmanaged variables are often the silent cause of slowdowns, moments of plant inactivity, scrap, and extra setup time. Factors that directly impact costs and productivity, yet are too often underestimated or handled only on a reactive basis.

Key critical variables include:

- Unpredictable material behavior

- Out-of-control tolerances

- Non-standard setups

- Lack of process monitoring at intermediate stages

Effectively managing these dynamics requires an integrated approach, built on experience, method, and technical control at every stage.

In this context, relying on partners with full control over tube processing means anticipating potential issues and minimizing margins of error.

A structured operating model, like the one applied by the Pantani Group, makes it possible to:

- Continuously monitor material behavior

- Keep tolerances within extremely tight limits

- Implement corrective actions before a variable becomes a real issue

The result? Greater efficiency. Less waste. Maximum production continuity.

This is not just a matter of technical precision: it is an approach to industrial responsibility that prioritizes customer peace of mind, repeatable results, and reliable performance even under the most challenging production conditions.

Would you like to learn more about how we can support you in reducing production variables and optimizing your processes? Contact us for a technical consultation.

21 November 2025

Pantani Group at Heat Exchanger World Americas 2025

Once again this year, we took part in Heat Exchanger World Americas 2025, one of the most relevant international trade fairs in the heat exchange industry. We traveled to Houston, the beating heart of the American industrial sector, to share our vision of reliability, innovation, and precision.

Above all, we were there to do what we do best: meeting people, listening to their needs, and building genuine, solid, long-lasting relationships.

The evolution of this industry is moving fast, and today customers are no longer looking for simple suppliers. They are looking for partners: reliable, present, and capable of providing concrete answers. That is exactly what we brought to the exhibition: not only our solutions, but a way of working that always puts dialogue at the center. Because that’s where the best projects begin.

Pantani Group never stands still. And once again, we were exactly where we needed to be.

12 February 2025

Pantani Group at EGYPES 2025: Innovation and Reliability for the Energy Sector

Once again this year, we confirm our presence at EGYPES – Egypt Energy Show 2025, the leading energy exhibition in North Africa and the Mediterranean area, taking place from February 17 to 19 at the Egypt International Exhibition Center in Cairo.

This event represents a unique opportunity to explore the latest innovations, gain deeper insights into industry challenges, and build strategic connections on a global scale.

We will present our advanced tube processing solutions for bending, finning, corrugation, and custom cutting, along with our latest innovation: extruded tubes. These solutions are designed to ensure maximum efficiency, fast delivery times, and uncompromising quality.